SIRTEF has got inside personnel qualified by the CICPND and certified at the 2nd level to make Non-Destructive Controls on steel wire ropes, slings and lifting accessories with the following methods:

Penetrating Liquids

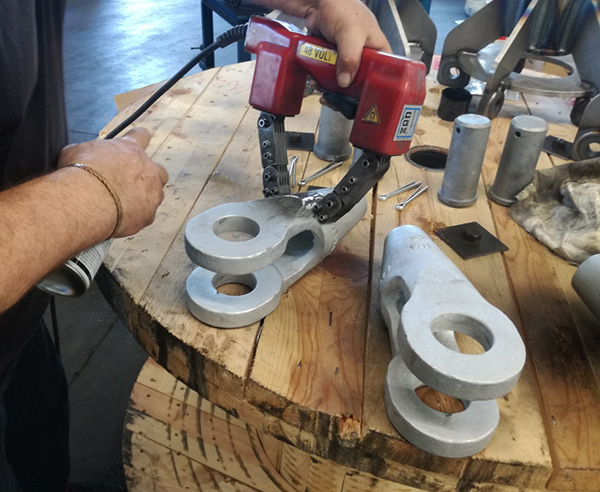

This kind of control is carried out to highlight defects on surfaces of any kind of material (castings, welding, pipes, etc.). The non-destructive test method with penetrating liquids is based on visual examination of the surface after the application, in sequence, of a penetrating product and a detector one.

The method makes all discontinuities visible on the surface as they normally are not visible or are hardly visible to the naked eye instead. Here below technical details:

- Controllable surfaces:

Actually, all non-porous surfaces, areas without grooves or areas able to absorb penetrating liquids. - Detectable Defects:

Surface defects such as cracks, porosity, folds and incisions - Functionality:

Easy to use – applicable on site – sensitive to even apparently un-significant defects - Application:

Surface controls on non-porous materials

Magneto-scope Control

This kind of control is based on the deviation the magnetic field lines, as being induced in a ferromagnetic material, undergo at the presence of some discontinuity.

It is used in the control of welding, castings, etc.

- Detectable Features:

Magnetic flow dispersed due to superficial or sub-superficial discontinuities such as: cracks, cavities and inclusions - Functionality:

Sensitive to both surface and sub-surface defects - Application:

Surface and sub-surface controls on all ferromagnetic materials