Rigging screws are one of the most used fitting in combination with steel wire rope sling in lashing and tensioning operations.

There are two big kind of rigging screw in the lift market, the first follows the american standard “Federal Specification FF-T-79lb Type 1, Class Form1 5” and this type of rigging screw is recognized in the Crosby HG series. These are high performance items with UNC thread, safety factor 5 and hot dip galvanizing; these rigging screw can also be used for linear-pull operations for port cranesground anchorages, antennas, torches, hanging bridges and other special applications.

The second family is rigging screws with metric thread, safety factor of 4 and zinc plating, these items often referred to as “commercial” are mostly dedicated to lashing operations.

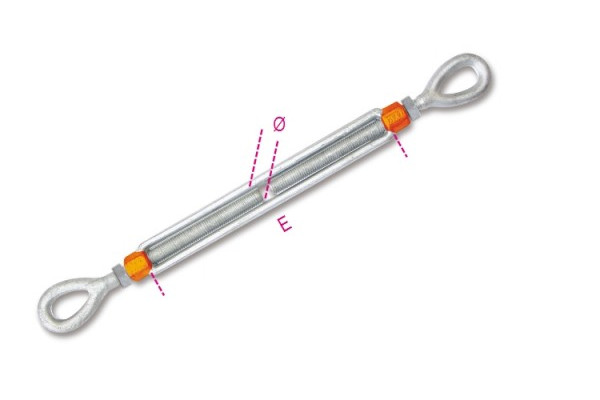

The rigging screws may have different end terminals based on the coupling necessity; forks with pins, round or elongated eyes, hooks and threaded ends.

In case of need the terminals can be fitted with locking nuts.