On 2022, December, the 18th is going to take place an unusual final match of the next Fifa World Cup, first-ever on Arab Countries, hosted in Qatar exactly one-hundred-forty-four years far from the beginning of its unification (18/12/1878), credit to Sheikh Jassim bin Mohammed Al Thani.

The Stadiums in Qatar for the 2022 World Cup

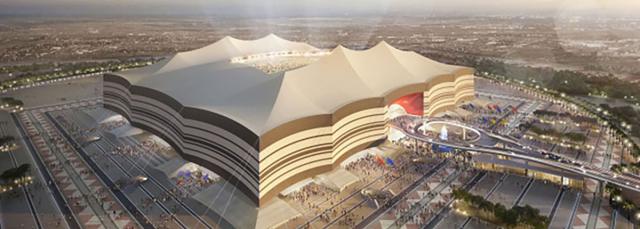

The Happening greatest events are going to take place at the Iconic Stadium in Lusail City, building expected to host approximately 90-thousand people, where the two finalist teams will play their victory.

The others stadiums scenes of the competition, according to the buyer Aspire Zone Foundation’s instructions, should all be accomplished within 2020. Two of them named Al Wakra Stadium (15 Km. south from Doha) and Al-Bayt Stadium (Al Khor, 45 Km. north from Doha) should be finished within 2018 indeed.

The facility in the process of installation near Al Khor, took its name of Al-Bayt from the traditional Bedouin tent (Bayt Al Sha’ar), to which got inspired the German architect Albert Speer jr. to design a structure closely reproducing its silhouette.

Al-Bayt stadium will even hold some “Italian taste” thanks to Galfar Al Misnad, Salini Impregilo and Cimolai spa consortium, which win the approximately 770 million contract for the construction, the installation and the maintenance of the bulding.

The Al-Bayt Stadium Project and the role of SIRTEF

The structure will host 60.000 audience settled on the 320 x 280 mtr. steel structure 73 mtr. tall made by Cimolai, as far as the retractable roof frame with its membrane cover.

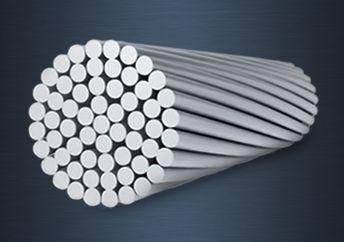

The retractable roof consists of 72 radial cantilevered trusses stabilized by secondary tangential framing. The system is engineered to complete its closing cycle in twenty minutes and will be moved thanks to some Verope 8 strands Compacted Plastic Layer Steel Wire Ropes type Veropro-8 and Veropower-8, with diameters 10 mm. and 22 mm. for a total amount of almost 1700 mtr. and others 900 mtr. of diameter 30 mm. Spiral Strands.

Execution

The pilot wire ropes (d.10 e 22 mm) have been set up at SIRTEF H.Q., equipped with standard sockets made by Van-Mechelen Ropeblock and Verope steel wire ropes both exclusive distributed in Italy by SIRTEF.

For the Structural Slings some specific design Ends Fittings have been used, suitable to fit the project needs. The supply had been managed complying with strict specifications, including the technical details analysis and the particular testing activities for the validation of chemical and mechanical properties of the products used.

All the stages have been made making use of the own internal Laboratory and in collaboration with some external qualified laboratories.

In order to ensure the wire ropes’ at work-duration, and their protection against any possible deterioration-determining factor, all the elements (wire ropes and sockets) have been supplied with zinc coating finishing.

SIRTEF provided the execution of the needed wire ropes length and the Spelter Sockets assembly through Wirelock cold pouring in accordance to the current EN 13411-4 regulations and as per RINA approved SIRTEF procedure.

Sockets Assembly Detail:

Ropeblock opened type OSS at one side,

Special Cimoali design type at the other side

Credits: The Pictures are taken from web sites: http://www.psc.it and http://stadiumdb.com