Last month in Ravenna at OMC 2015 exhibition, all the visitors had the chance to admire a faithful reproduction of a working closing machine.

Last month in Ravenna at OMC 2015 exhibition, all the visitors had the chance to admire a faithful reproduction of a working closing machine.

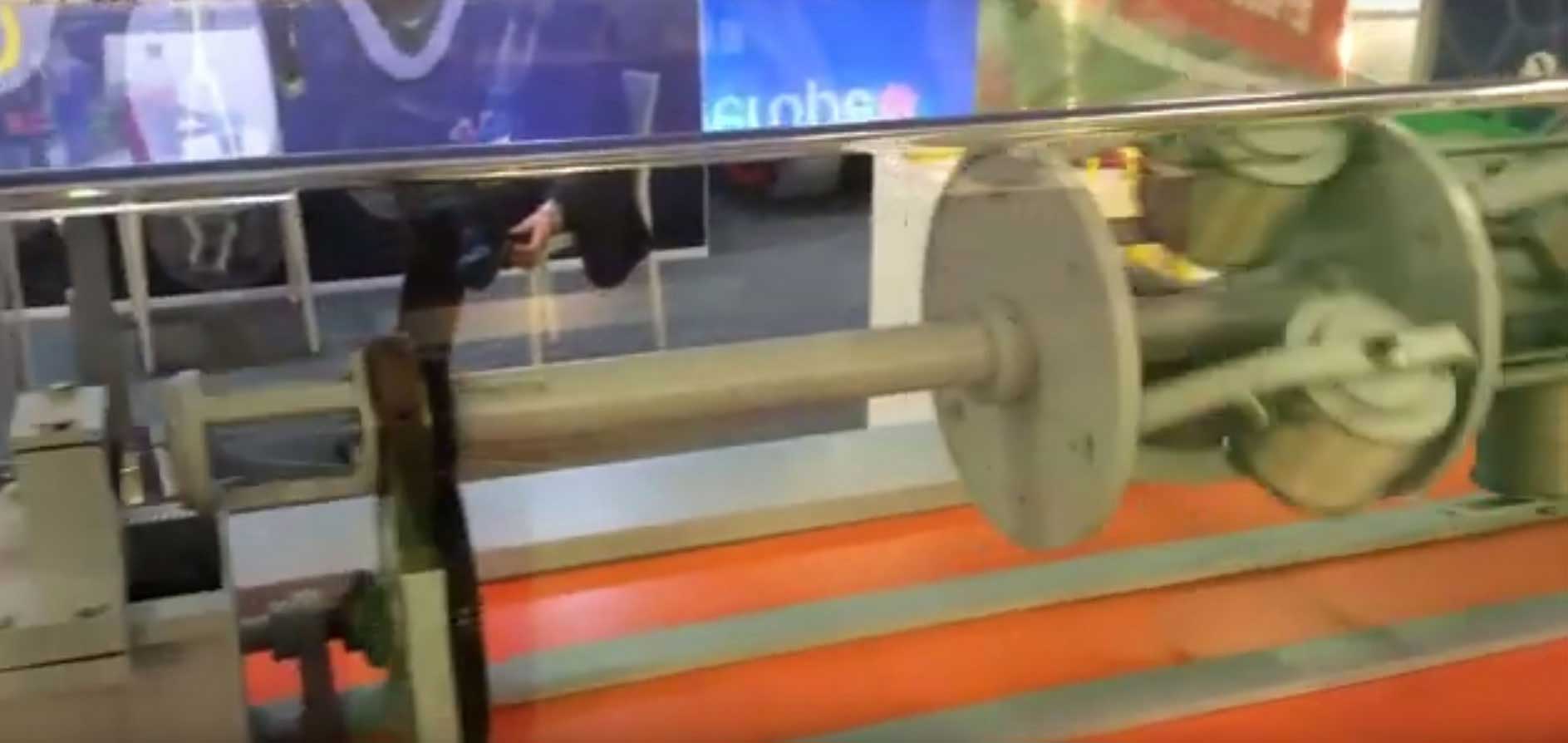

This specific device, that is normally used to manufacture any kind of steel wire ropes, was showed at SIRTEF stand and captured the attention of all the guests. Let’s find out some technical details.

The “mini-closer” is able to perform the final stage of the production of a steel wire rope, this specific phase is named “closing“. Although a reproduction, It perfectly completes the construction of a 6 strands steel wire rope with steel core, the final diameter is 2.5 mm.

In the machine, you can find all the components of a real “planetary closerâ€; there is the reel able to provide the central core that runs centrally along the horizontal axis of it, positioned on the back of the head. Then, immediately after, there are all the bobbins where are coiled the single strands with 0,75 mm. diameter which complete the production of the steel wire rope .

Each reel is equipped (as is in the real machine) of a brake, which ensures a proper tension of the single strand, so that while closing, the strands find the right place, ensuring geometric regularity to the rope itself.

Once loaded all the strands on the core and completed the manufacture of the steel wire rope, the rope itself passes in a capstan system, made by a pair of large multiple grooves wheels, which, thanks to an adequate number of driving gears, allows the elimination of possible tensions born in the steel wire rope.

Once loaded all the strands on the core and completed the manufacture of the steel wire rope, the rope itself passes in a capstan system, made by a pair of large multiple grooves wheels, which, thanks to an adequate number of driving gears, allows the elimination of possible tensions born in the steel wire rope.

These operations take place before the rope goes definitevely on the storage reel.

The reproduction of the Verope closing machine at work at OMC 2015