HOME > PRODUCTS > STEEL WIRE ROPES >

Spiral Strands

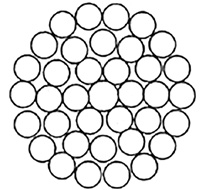

The Spiral strands steel wire ropes spiroid are made by harmonic high-strength steel wires hot-dip galvanized. They must be composed of layers of round wires helically wound around a central core.

The wires outer layers shape should be such as to ensure a mutual locking of the wires in order to obtain a compact section.

The main features of corrosion-resistance of the wire must conform UNI EN 12385-10, while galvanizing and wire ductility must comply with the standards UNI EN 10264 class A.

The steel wire ropes for structural applications must be pay close plant in order to eliminate any inelastic deformation and to stabilize the initial elasticity module.

The pre-stretching is carried out with different cycles from 10% to 50% of the minimum breaking force in order to stabilize the elasticity module.

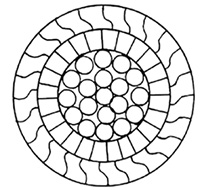

The steel wire ropes end-terminations must be anchored with elements resistant to steel wire rope breaking strength.

The connection with the rope must meet the requirements of the UNI EN 13411-4, with the use of resins or jet of pure zinc in the molten state.

Structural Spiral Strands

This kind of “rope” it is specifically dedicated to static applications such as: structural constructions, bridges and everywhere it is needed to get lighter load bearing components respect to the standard materials (concrete, steel bars, lamellar wood, etc.) and at the same time related to aesthetic concerns.

SIRTEF has developed several projects with spiral strands and special end terminations such as bridges, footpaths, frontispiece of fascinating buildings, panorama mountain structures, motorway toll houses, etc.

Further to the engineering, manufacturing and installation of pennants and related steel components, we are able to test all the products thanks to specific devices and skilled and qualified personnel. We can perform NDT (MPI, UT, PT) if it is the case witnessed by Third Parties qualified I.A.C.S.(Lloyd’s Register, R.I.Na., D.N.V., B.V. , A.B.S., etc.).

We have a pre-stretching line in house that allows us to perform proof load tests and to tension the strands during the measuring and cutting activities.